Life Expectancy Curves... Human vs Stock 7.3L

#16

Thanks! I just spent 20 glorious minutes reading that.

Here's a motto to live by if you want. I thought it was fitting. It's a sign that hangs in my hairdresser's booth.

"LIFE SHOULD NOT BE A JOURNEY TO THE GRAVE WITH THE INTENTIONS OF ARRIVING SAFELY IN AN ATTRACTIVE AND WELL PRESERVED BODY, BUT RATHER TO SKID IN SIDEWAYS.CHOCOLATE IN ONE HAND BEER IN THE OTHER THOROUGHLY USED UP, TOTALLY WORN OUT AND SCREAMING, "WOO HOO, WHAT A RIDE!"

lol

Here's a motto to live by if you want. I thought it was fitting. It's a sign that hangs in my hairdresser's booth.

"LIFE SHOULD NOT BE A JOURNEY TO THE GRAVE WITH THE INTENTIONS OF ARRIVING SAFELY IN AN ATTRACTIVE AND WELL PRESERVED BODY, BUT RATHER TO SKID IN SIDEWAYS.CHOCOLATE IN ONE HAND BEER IN THE OTHER THOROUGHLY USED UP, TOTALLY WORN OUT AND SCREAMING, "WOO HOO, WHAT A RIDE!"

lol

__________________

Jody & Diane Tipton- DP-Tuner®

FTE Legacy Sponsors since 2006

Custom tuning for 7.3l, 6.0l, 6.4l,6.7l, Ecoboost,

Get Tuned! 828-221-0076 ext. 802

Become our Facebook Fan

Jody & Diane Tipton- DP-Tuner®

FTE Legacy Sponsors since 2006

Custom tuning for 7.3l, 6.0l, 6.4l,6.7l, Ecoboost,

Get Tuned! 828-221-0076 ext. 802

Become our Facebook Fan

The following users liked this post:

#17

Thanks! I just spent 20 glorious minutes reading that.

Here's a motto to live by if you want. I thought it was fitting. It's a sign that hangs in my hairdresser's booth.

"LIFE SHOULD NOT BE A JOURNEY TO THE GRAVE WITH THE INTENTIONS OF ARRIVING SAFELY IN AN ATTRACTIVE AND WELL PRESERVED BODY, BUT RATHER TO SKID IN SIDEWAYS.CHOCOLATE IN ONE HAND BEER IN THE OTHER THOROUGHLY USED UP, TOTALLY WORN OUT AND SCREAMING, "WOO HOO, WHAT A RIDE!"

lol

Here's a motto to live by if you want. I thought it was fitting. It's a sign that hangs in my hairdresser's booth.

"LIFE SHOULD NOT BE A JOURNEY TO THE GRAVE WITH THE INTENTIONS OF ARRIVING SAFELY IN AN ATTRACTIVE AND WELL PRESERVED BODY, BUT RATHER TO SKID IN SIDEWAYS.CHOCOLATE IN ONE HAND BEER IN THE OTHER THOROUGHLY USED UP, TOTALLY WORN OUT AND SCREAMING, "WOO HOO, WHAT A RIDE!"

lol

The following users liked this post:

#18

After due consideration I concluded that this "red curve" just happens to be a very accurate fit to the International B10 and B50 mileages for their T444E ...so I'll interrupt my reply to you and answer this related question...

Here's a copy and paste which indicates that when it comes to the T444E and the 7.3L Power Stroke ...International has a long history of engine development that could've been analyzed to come up with their numbers.

..."The International engine that started it all was the 6.9 IDI. The indirect injection 6.9 was simple in design, naturally aspirated, made 170 hp @ 3300 RPM, and 315 lb-ft of torque @ 1400 RPM. The 6.9 was released in 1983 and gained instant popularity. So much in fact, that Ford had to ask International to increase production of the engines, a move that produced a great stream of revenue for both companies. Sometime in 1987, the bore of the 6.9 was increased from 4.00 in to 4.11 inches, and the 7.3 IDI was born. It was in 1994 that the 7.3 IDI became a direct injected, turbocharged diesel and proudly named, the Power Stroke"...

...Here's a motto to live by if you want. I thought it was fitting. It's a sign that hangs in my hairdresser's booth.

"LIFE SHOULD NOT BE A JOURNEY TO THE GRAVE WITH THE INTENTIONS OF ARRIVING SAFELY IN AN ATTRACTIVE AND WELL PRESERVED BODY, BUT RATHER TO SKID IN SIDEWAYS.CHOCOLATE IN ONE HAND BEER IN THE OTHER THOROUGHLY USED UP, TOTALLY WORN OUT AND SCREAMING, "WOO HOO, WHAT A RIDE!"

lol...

"LIFE SHOULD NOT BE A JOURNEY TO THE GRAVE WITH THE INTENTIONS OF ARRIVING SAFELY IN AN ATTRACTIVE AND WELL PRESERVED BODY, BUT RATHER TO SKID IN SIDEWAYS.CHOCOLATE IN ONE HAND BEER IN THE OTHER THOROUGHLY USED UP, TOTALLY WORN OUT AND SCREAMING, "WOO HOO, WHAT A RIDE!"

lol...

So "life extension" is really just a process which accomplishes some combination of ...dulling the saw ...strengthening the board or making it wider ...repairing some of the cut material as the sawing progresses ...or striking a "bargain" with whoever is doing the sawing!

#19

Death by a thousand cuts...

I haven't posted for awhile because my spare time has been consumed by ...repairing leaks in my 5er ...watching football games and sports car races ...and working on a new computer model for a 7.3L engine that calculates parameters for each 1* of crankshaft rotation!

On the subject of my model ...I need the weight of a piston and the weight of a rod and the center-to-center length of a rod! Also to help with my analysis of piston friction ...if anyone has access to a 7.3L engine with the heads removed please use a torque wrench and measure the average TQ required to rotate the crankshaft about 90* or so and then repeat this measurement 4 or 5 times so I can average those results!

On the subject of sports car races ...I heard the expression "they suffered death by a thousand cuts" used to describe all the little things that went wrong for one team prior to their final race ending problem which occurred during the 23rd hour of the recent Daytona 24 hour race ...and that old saying about "death" gave me yet another idea for how to describe the "life expectancy" of a 7.3L engine!

As I watched the interview with the 2nd place driver "Scott Pruett" I thought ...based on his looks and last name he might be the son of "Jerry" who was a top "sponsored" driver that I raced against as an "amateur" in the 1960's ...but as can be seen below after I dug up this old press clipping I discovered the last names aren't spelled quite the same ...so I guess "Scott Pruett" looking like the "Jerry Truitt" that I knew is just one more of life's never ending coincidences!

On the subject of football games ...quarterbacks are supposedly the "heart" of the team ...and several teams with the "oldest" quarterbacks lost and one team with the "youngest" quarterback lost ...so I guess the "life expectancy" message for the playoffs has to do with..."old age wear out" and "infant mortality rate" ...and evidently the most reliable "quarterback engine" is one that's accumulated enough "football miles" to be considered "broken in" but not so many miles to be considered "worn out" and on the verge of "breaking down"!

On the subject of "diesel engine" life expectancy ...if a 7.3L engine lasts for the B90 life expectancy of 440K miles indicated by the red line in my previous graph ...which is a 95 year equivalent human age ...then the engine's crankshaft completes 1 billion (1x10^9) revolutions ...and the human's heart completes 3.5 billion (3.5x10^9) beats!

However a 7.3L engine has 8 hearts ...and if all 8 pistons keep pumping out power stroke heart beats for the entire B90 life expectancy ...then a 7.3L engine completes 4 billion (4x10^9) power stroke heart beats during its lifetime which is more than the human's 3.5 billion (3.5x10^9) lifetime heart beats ...and unlike humans who are declared dead when their heart stops beating ...a 7.3L engine can live with some of its hearts not producing useful power stroke beats ...and I recently read a thread where a 7.3L engine with only 7 functional hearts actually pulled a 5er in order to avoid a tow!

Well suffering "death by a thousand cuts" is quite possibly the "worst" way for a human to die ...but it's actually the "best" way for a 7.3L engine to die because...

...so if something is going to eventually kill a 7.3L engine anyway ...then the "best" way for the engine to die is from the 16 billion (1.6x10^10) small cuts that accumulate on its cylinder walls, piston skirts, and piston rings as the pistons slow to a complete stop at TDC and BDC during each rotation of the crankshaft!

During the engine's B90 lifetime each piston slides along the cylinder wall for 132K total miles ...and for a human that much sliding would wear out a lot of shoe leather ...but for a piston most of the wear occurs during the relatively short sliding intervals corresponding to the 500 million (5x10^8) reversals in piston direction at TDC between the end of the compression stroke and the beginning of the power stroke ...so for now I'll concentrate my analysis on those critical wear intervals!

For anyone who's rubbed two sticks together to start a campfire it must seem "counterintuitive" to suggest that "slow to no" piston speed produces more "friction wear" than is produced by "higher" piston speeds so I'll start by discussing some basic "tribology" ...the science of the mechanisms of friction, lubrication, and wear of interacting surfaces that are in relative motion.

If the desired state of "hydrodynamic lubrication" could be continuously maintained between all of the rubbing and sliding surfaces in an engine ...then there'd be essentially no wear at all ...and the engine would last until some component underwent enough "fatigue stress cycles" to finally weaken and break!

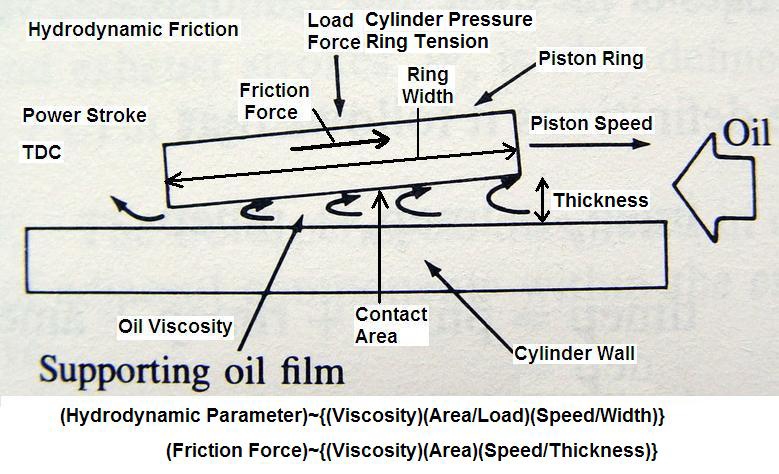

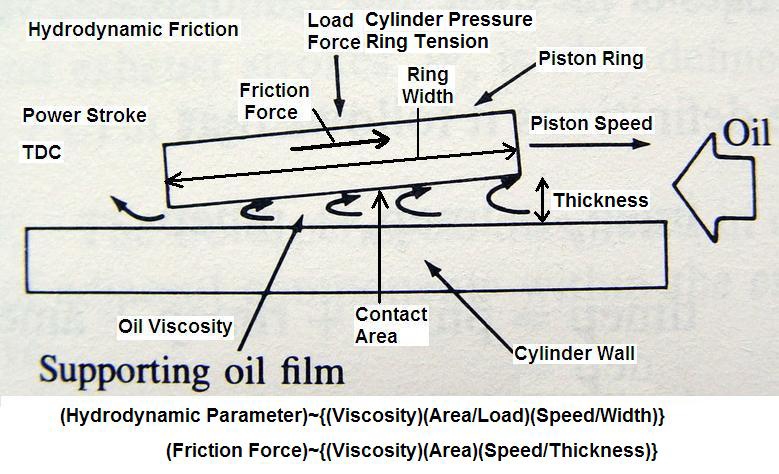

As is suggested in the first of the three pictures below ...the "hydrodynamic lubrication" of piston rings sliding along on a cylinder-wall oil film is somewhat akin to water skiing ...but with the skis oriented "sideways" to the direction of travel instead of "lengthways"!

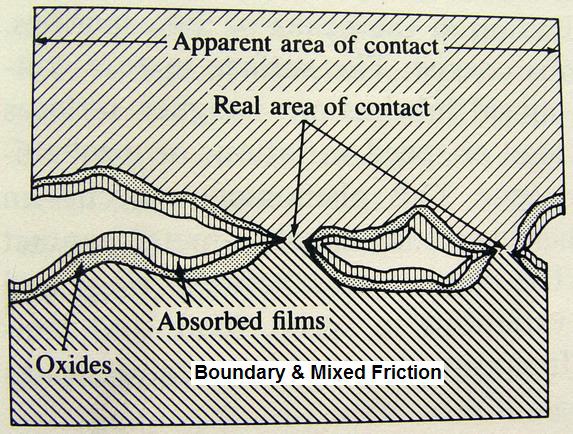

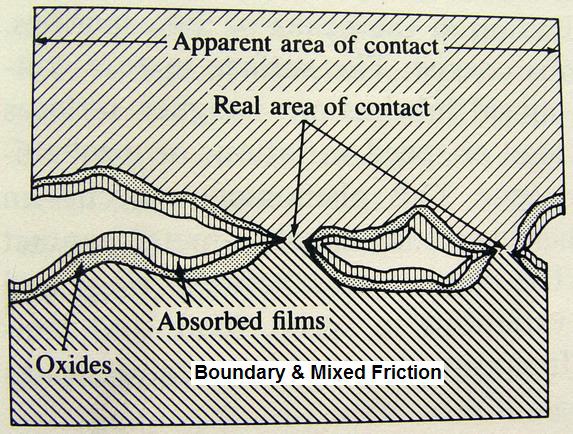

If a water-skier ...is overweight and applies too much "Load" relative to the contact "Area" of his skies ...or his "Speed" is too slow relative to the "Width" of his skies ...or if the "Viscosity" of the water is too low relative to the combined effects of the two previous considerations ...then the skier sinks into the water and his "hydrodynamic parameter" ...which is proportional to {(Viscosity)(Area/Load)(Speed/Width)} ...sinks into the regime of "mixed or boundary lubrication" and the water-skier scuffs the bottoms of his skies ...just like what's shown for some "metal-to-metal contact" in the third picture!

The first picture below also indicates that ...(Friction Force)~{(Viscosity)(Area)(Speed/Thickness)} ...which seems to suggest that frictional wear increases with increasing piston "Speed" ...but this equation only applies to "Hydrodynamic Lubrication" where the oil film "Thickness" is greater than the peak-to-peak surface roughness ...and this means that even though the resulting "Friction Force" ...which is the tangential force needed to move the piston at a given "Speed" ...increases in portion to piston "Speed" ...this "Friction Force" is actually being used to overcome the "sheer strain" of the oil film and not to overcome the resistance of "metal-to-metal contact" which is the kind of friction that causes wear!

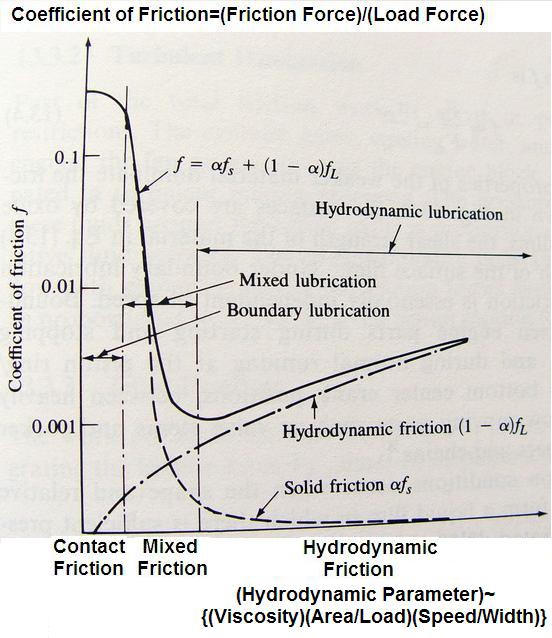

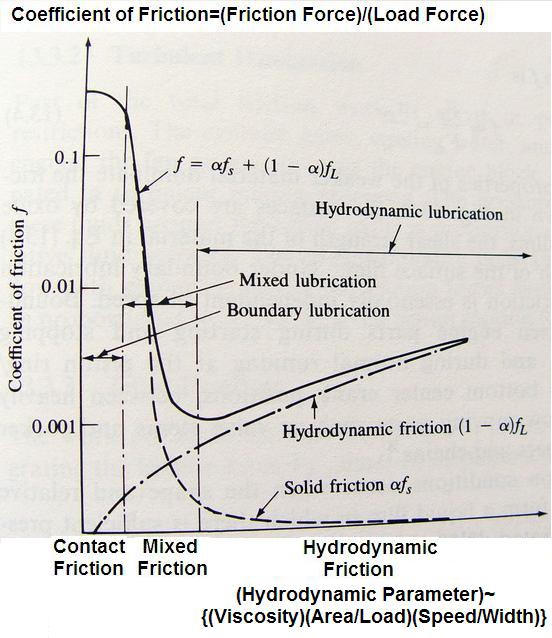

As can be seen in the second picture above ...increasing the value of ...(Hydrodynamic Parameter)~{(Viscosity)(Area/Load)(Speed/Width)} ...moves the operating point to the right ...which is further into the regime of "Hydrodynamic Lubrication" ...and this increases the ...Coefficient of Friction=(Friction Force)/(Load Force) ...and thereby increases the percentage of the Power Stroke HP that's lost to "frictional heating" of the oil ...but I'd rather have a little hotter oil and a little less FWHP due to using a higher "Viscosity" oil than to go for a higher MPG by using a lower "Viscosity" oil which increases the chance for more "metal-to-metal contact"!

I'll post another installment after my "mouse hand" recovers enough small muscle control to annotate some more pictures! Giving posts using pictures is a lot more work than just using equations! Among other things I'm going to work up a graph that compares the "Viscosity" of SAE 15W/40 oil and SAE 5W/40 oil ...and looking at that graph now I see ...at 100*F the "Viscosity" of SAE 15W/40 oil is about twice as large as the "Viscosity" of SAE 5W/40 oil!

On the subject of my model ...I need the weight of a piston and the weight of a rod and the center-to-center length of a rod! Also to help with my analysis of piston friction ...if anyone has access to a 7.3L engine with the heads removed please use a torque wrench and measure the average TQ required to rotate the crankshaft about 90* or so and then repeat this measurement 4 or 5 times so I can average those results!

On the subject of sports car races ...I heard the expression "they suffered death by a thousand cuts" used to describe all the little things that went wrong for one team prior to their final race ending problem which occurred during the 23rd hour of the recent Daytona 24 hour race ...and that old saying about "death" gave me yet another idea for how to describe the "life expectancy" of a 7.3L engine!

As I watched the interview with the 2nd place driver "Scott Pruett" I thought ...based on his looks and last name he might be the son of "Jerry" who was a top "sponsored" driver that I raced against as an "amateur" in the 1960's ...but as can be seen below after I dug up this old press clipping I discovered the last names aren't spelled quite the same ...so I guess "Scott Pruett" looking like the "Jerry Truitt" that I knew is just one more of life's never ending coincidences!

On the subject of football games ...quarterbacks are supposedly the "heart" of the team ...and several teams with the "oldest" quarterbacks lost and one team with the "youngest" quarterback lost ...so I guess the "life expectancy" message for the playoffs has to do with..."old age wear out" and "infant mortality rate" ...and evidently the most reliable "quarterback engine" is one that's accumulated enough "football miles" to be considered "broken in" but not so many miles to be considered "worn out" and on the verge of "breaking down"!

On the subject of "diesel engine" life expectancy ...if a 7.3L engine lasts for the B90 life expectancy of 440K miles indicated by the red line in my previous graph ...which is a 95 year equivalent human age ...then the engine's crankshaft completes 1 billion (1x10^9) revolutions ...and the human's heart completes 3.5 billion (3.5x10^9) beats!

However a 7.3L engine has 8 hearts ...and if all 8 pistons keep pumping out power stroke heart beats for the entire B90 life expectancy ...then a 7.3L engine completes 4 billion (4x10^9) power stroke heart beats during its lifetime which is more than the human's 3.5 billion (3.5x10^9) lifetime heart beats ...and unlike humans who are declared dead when their heart stops beating ...a 7.3L engine can live with some of its hearts not producing useful power stroke beats ...and I recently read a thread where a 7.3L engine with only 7 functional hearts actually pulled a 5er in order to avoid a tow!

Well suffering "death by a thousand cuts" is quite possibly the "worst" way for a human to die ...but it's actually the "best" way for a 7.3L engine to die because...

...Even if nothing else kills a diesel engine beforehand... "tribology" ...will eventually cause enough wear of the cylinder wall, piston skirt, and piston rings so that the "heat of compression" produced during the compression stroke will be insufficient for "auto-ignition" of the fuel ...and analyzing when this "fatal wear out point" develops by calculating a "minimum required" compression test pressure reading will be one of the approaches I use to define when "engine death" occurs!...

During the engine's B90 lifetime each piston slides along the cylinder wall for 132K total miles ...and for a human that much sliding would wear out a lot of shoe leather ...but for a piston most of the wear occurs during the relatively short sliding intervals corresponding to the 500 million (5x10^8) reversals in piston direction at TDC between the end of the compression stroke and the beginning of the power stroke ...so for now I'll concentrate my analysis on those critical wear intervals!

For anyone who's rubbed two sticks together to start a campfire it must seem "counterintuitive" to suggest that "slow to no" piston speed produces more "friction wear" than is produced by "higher" piston speeds so I'll start by discussing some basic "tribology" ...the science of the mechanisms of friction, lubrication, and wear of interacting surfaces that are in relative motion.

If the desired state of "hydrodynamic lubrication" could be continuously maintained between all of the rubbing and sliding surfaces in an engine ...then there'd be essentially no wear at all ...and the engine would last until some component underwent enough "fatigue stress cycles" to finally weaken and break!

As is suggested in the first of the three pictures below ...the "hydrodynamic lubrication" of piston rings sliding along on a cylinder-wall oil film is somewhat akin to water skiing ...but with the skis oriented "sideways" to the direction of travel instead of "lengthways"!

If a water-skier ...is overweight and applies too much "Load" relative to the contact "Area" of his skies ...or his "Speed" is too slow relative to the "Width" of his skies ...or if the "Viscosity" of the water is too low relative to the combined effects of the two previous considerations ...then the skier sinks into the water and his "hydrodynamic parameter" ...which is proportional to {(Viscosity)(Area/Load)(Speed/Width)} ...sinks into the regime of "mixed or boundary lubrication" and the water-skier scuffs the bottoms of his skies ...just like what's shown for some "metal-to-metal contact" in the third picture!

The first picture below also indicates that ...(Friction Force)~{(Viscosity)(Area)(Speed/Thickness)} ...which seems to suggest that frictional wear increases with increasing piston "Speed" ...but this equation only applies to "Hydrodynamic Lubrication" where the oil film "Thickness" is greater than the peak-to-peak surface roughness ...and this means that even though the resulting "Friction Force" ...which is the tangential force needed to move the piston at a given "Speed" ...increases in portion to piston "Speed" ...this "Friction Force" is actually being used to overcome the "sheer strain" of the oil film and not to overcome the resistance of "metal-to-metal contact" which is the kind of friction that causes wear!

As can be seen in the second picture above ...increasing the value of ...(Hydrodynamic Parameter)~{(Viscosity)(Area/Load)(Speed/Width)} ...moves the operating point to the right ...which is further into the regime of "Hydrodynamic Lubrication" ...and this increases the ...Coefficient of Friction=(Friction Force)/(Load Force) ...and thereby increases the percentage of the Power Stroke HP that's lost to "frictional heating" of the oil ...but I'd rather have a little hotter oil and a little less FWHP due to using a higher "Viscosity" oil than to go for a higher MPG by using a lower "Viscosity" oil which increases the chance for more "metal-to-metal contact"!

I'll post another installment after my "mouse hand" recovers enough small muscle control to annotate some more pictures! Giving posts using pictures is a lot more work than just using equations! Among other things I'm going to work up a graph that compares the "Viscosity" of SAE 15W/40 oil and SAE 5W/40 oil ...and looking at that graph now I see ...at 100*F the "Viscosity" of SAE 15W/40 oil is about twice as large as the "Viscosity" of SAE 5W/40 oil!

#21

The end of an era...

I'm still trying to adjust my sleeping pattern ...after two successive nights of staying up past 4 AM the wife and I finally got to witness the last nighttime launch of a space shuttle ...and the billion dollar show was well worth the wait! We saw a daytime launch from this same RV park in 2001 ...but at night in addition to seeing the solid rocket boosters fall away ...we could see main engine power up to full throttle and also eventual engine shut down!

What if a 7.3L engine's life expectancy was the same as a space shuttle's life expectancy which is about two dozen trips? Well when you consider the earth's diameter is 7,925 miles and the shuttle's altitude is 125 miles ...that works out to 26K miles per orbit times 16 orbits per day equals 416K miles per day times 10 days per trip equals 4.2 million miles per trip times 24 trips equals 100 million miles over the shuttle's life expectancy ...which is a little more than a 7.3L engine's B90 life expectancy of 440K miles!

I'm doing this series of posts on engine wear and 7.3L engine life expectancy for the same reason I do any of my technical posts ...because analyzing diesels has become my retirement hobby ...and after retirement comes death ...and if I don't take the time to pass along some of the things I've learned before then I won't have another opportunity to do so ...at least that's my current theory on how death works!

In two different threads I gave a "direct quote" from a reference paper on engine wear ...and that quote caused so much confusion that I won't be quoting from reference sources again or even giving links to my sources ...I realize it's bad form to use material from reference sources without citing proper attribution ...however if you read my first installment you might recall that ...I've got a 2% probability of dying next year ...and the "smart money" would wager on the side of me dying before my C7 does ...so I won't be wasting any more of my remaining life expectancy by citing reference sources ...but I will gladly take the time to answer questions about anything I post ...and now for the real business at hand!

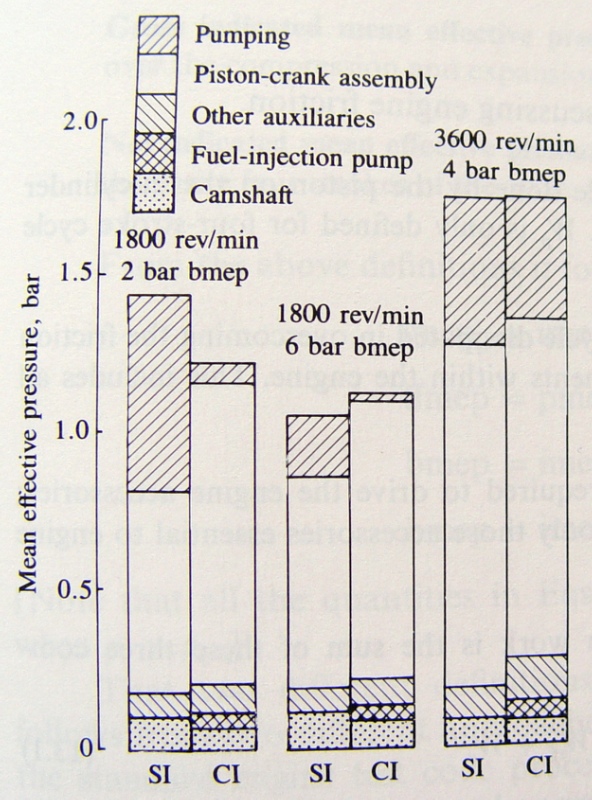

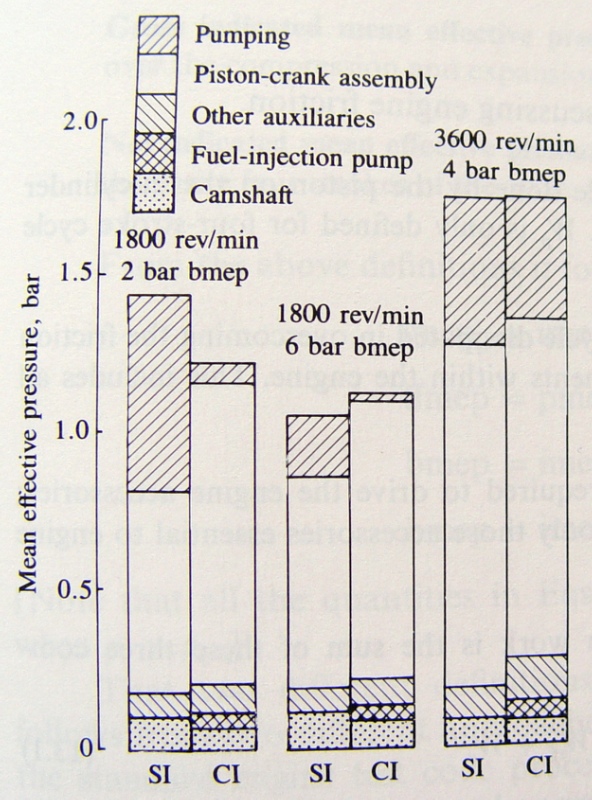

The graph below gives the categories and amounts of engine frictional loss for a gasser and a naturally aspirated diesel for several operating loads. The pumping losses shown are caused by "air friction" and "pressure differences" ...and in naturally aspirated engines pumping loss increases as RPM^2 ...but in my turbo-diesel model I treat pumping loss as a separate non-frictional loss term ...because I'm interested in the frictional losses between moving surfaces which causes wear ...and in this category the frictional loss of the piston skirts/rings rubbing against the cylinder walls accounts for about 80% of the total frictional loss shown for the piston-crank assembly ...and this means the friction of the piston skirts/rings accounts for about 70% of the total engine friction!

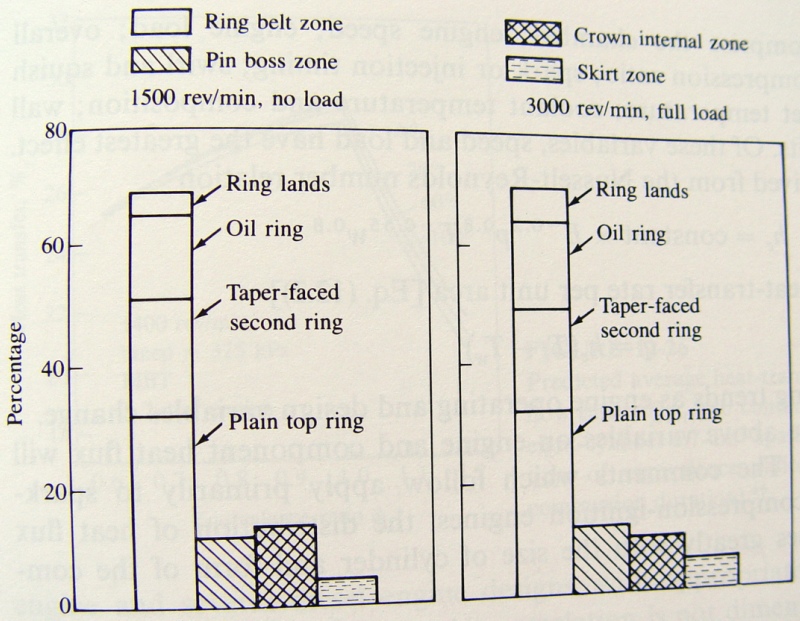

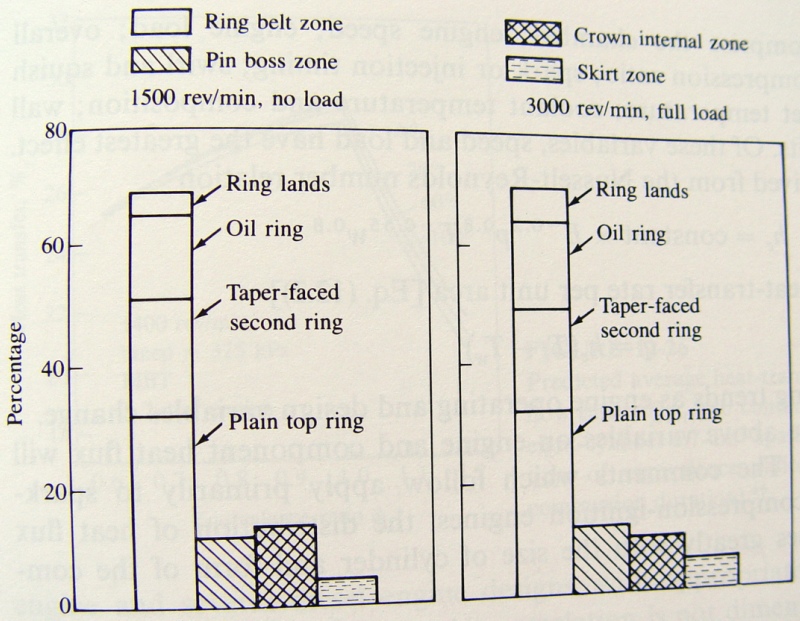

Well piston skirt/ring friction causes heat build up ...and heat build up leads to more friction ...and there's also the heat load from the combustion to consider! The graph below is for a DI diesel with a Bore, Stroke, and Compression Ratio that's about the same as for a 7.3L engine ...and the graph gives the "percentage of heat flow" from the combustion chamber that various portions of a piston absorb ...and as can be seen the upper ring portions of the piston take the brunt of the heat load!

So considering the above graphs it's not surprising that in the course of a 7.3L engine's B90 life expectancy ...which is roughly 440K miles and 1 billion crankshaft revolutions ...the decline in the engine's durability and efficiency is largely determined by the wear of the piston skirts/rings and cylinder walls. As the piston skirts/rings and cylinder walls wear ...there's a gradual loss of FWHP ...and there's a gradual increase in fuel consumption, oil consumption, blowby, and exhaust emissions.

The wear rate of the piston skirts/rings and cylinder walls is initially high when an engine is new ...and during the break-in miles the wear rate gradually decreases ...and finally the wear rate reaches a fairly stable lower steady-state value during the remaining miles of the engine's life expectancy.

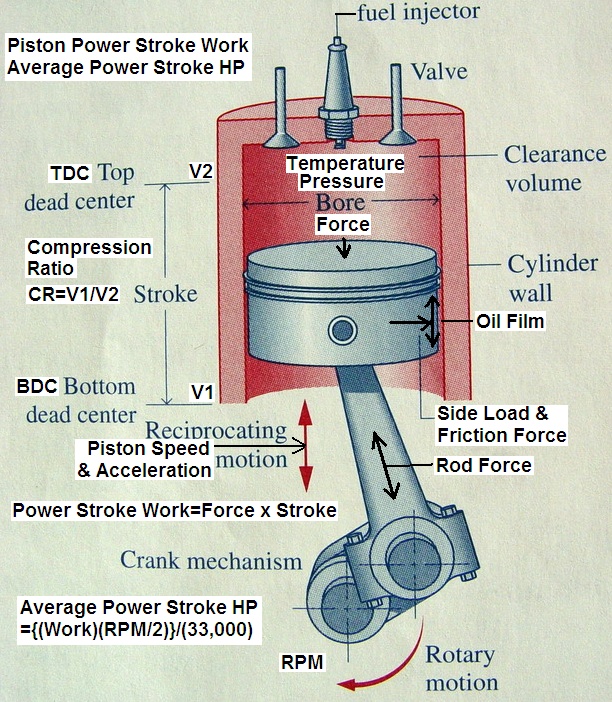

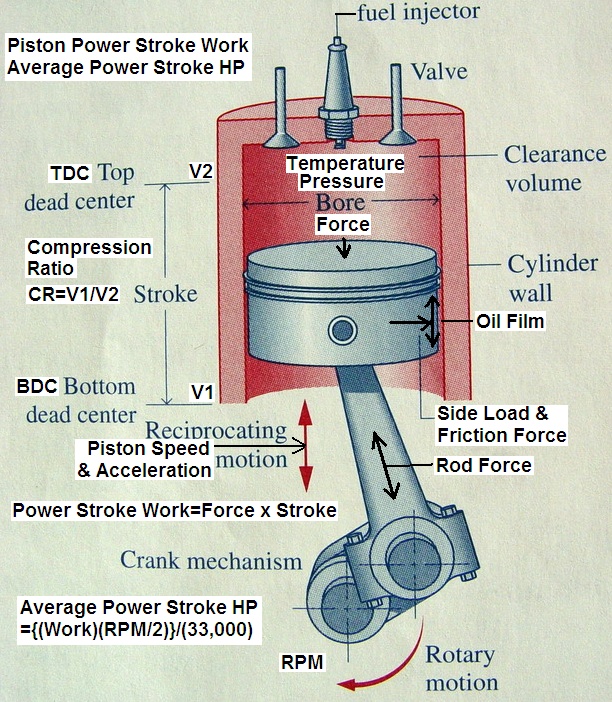

In addition to other features that I'll cover in future installments ...the picture below indicates the various forces that combine to determine the tangential friction force between the piston skirt/ring and the cylinder wall. The combustion pressure applies a pressure force to the top of the piston ...and this pressure force is applied via the piston pin to the rod. The reciprocating motion of the piston produces an inertial force that's applied by the rod to the piston pin. The net force in the rod times the sine of the angle between the rod and the cylinder vertical centerline gives the side-load force on the piston ...and multiplying the side-load force by the coefficient of friction gives the tangential friction force between the piston skirt/ring and the cylinder wall.

However as can be seen in this graph... http://ernesteugene.com/FTE3/Oil_Friction.jpg ...the coefficient of friction depends on the type of lubrication that is obtained between the piston skirt/ring and the cylinder wall ...and the lubrication type varies from mixed or boundary lubrication near TDC of the power stroke to full hydrodynamic lubrication during the center portions of the piston strokes. From here on if I refer to a picture I've already posted I'll give the link to it ...and clicking on that link should open the picture in a separate window.

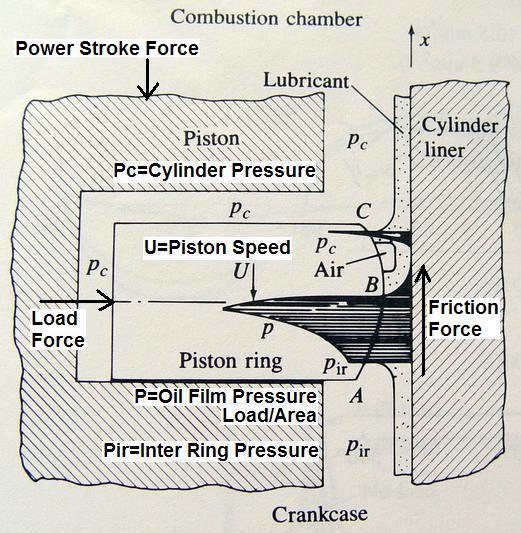

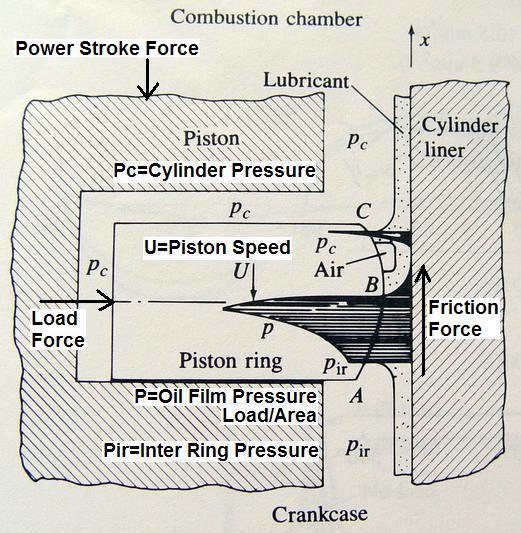

The picture below shows the beginning of a power stroke ...and as can be seen the full value of the combustion pressure leaks behind the first compression ring and pushes that ring against the cylinder wall with a pressure force which adds to the spring tension force in the ring and also adds to the side-load force on the piston that was previously considered above ...and a lesser value of the combustion pressure leaks behind the second compression ring and pushes that ring against the cylinder wall with a somewhat lesser force compared to the force pushing the first compression ring ...and a even lesser value of the combustion pressure leaks behind the next ring etc... and for a healthy engine with a normal amount of blowby about 1% of the mass of cylinder gas winds up leaking down to the crankcase.

There're many mechanisms that contribute to the wear of the piston skirts/rings and cylinder walls. The three most important wear mechanisms are ...mixed or boundary lubrication, abrasion, and corrosion. Mixed or boundary lubrication occurs when the oil film between the piston skirts/rings and cylinder walls is thin enough to allow some metal-to-metal contact. Abrasion results from the cutting action of hard particles in the oil that are small enough to enter the clearance space between the piston skirts/rings and the cylinder walls. Corrosion results from adverse chemical reactions associated with the decomposition of diesel fuel and engine oil and corrosion is occurring all the time ...even when the engine isn't running!

Other than the B10 and B50 numbers for a T444E ...I haven't found any wear data for a 7.3L engine ...however by using normalized parameters such as piston speed, mean effective pressure, FWHP per piston area, FWHP per CID, and others ...I'm attempting to use measured data from test engines and from lab simulators that generate accelerated mechanical wear of piston skirts/rings and cylinder walls ...and results from mathematical wear models ...to shed some light on the potential wear performance of a 7.3L engine for various levels of FWHP generated at various values of RPM.

To help calculate these estimates ...I need the weight of a piston and the weight of a rod and the center-to-center length of a rod ...and to aid my analysis of piston friction I need for someone who has access to a 7.3L engine with the heads removed to use a torque wrench and measure the average TQ required to rotate the crankshaft about 90* or so and then repeat this measurement 4 or 5 times so I can average those results ...and I also need to know if a 7.3L engine uses an offset wrist pin ...and I'm beginning to think that to get this information I might need to start a thread on another forum where there's more interest and/or more knowledge about the innards of a 7.3L engine?

I'll start the next installment by giving some graphs of measured data on several diesel engines of oil film thickness and tangential friction force between the piston skirt/ring and the cylinder wall.

I'm still trying to adjust my sleeping pattern ...after two successive nights of staying up past 4 AM the wife and I finally got to witness the last nighttime launch of a space shuttle ...and the billion dollar show was well worth the wait! We saw a daytime launch from this same RV park in 2001 ...but at night in addition to seeing the solid rocket boosters fall away ...we could see main engine power up to full throttle and also eventual engine shut down!

What if a 7.3L engine's life expectancy was the same as a space shuttle's life expectancy which is about two dozen trips? Well when you consider the earth's diameter is 7,925 miles and the shuttle's altitude is 125 miles ...that works out to 26K miles per orbit times 16 orbits per day equals 416K miles per day times 10 days per trip equals 4.2 million miles per trip times 24 trips equals 100 million miles over the shuttle's life expectancy ...which is a little more than a 7.3L engine's B90 life expectancy of 440K miles!

I'm doing this series of posts on engine wear and 7.3L engine life expectancy for the same reason I do any of my technical posts ...because analyzing diesels has become my retirement hobby ...and after retirement comes death ...and if I don't take the time to pass along some of the things I've learned before then I won't have another opportunity to do so ...at least that's my current theory on how death works!

In two different threads I gave a "direct quote" from a reference paper on engine wear ...and that quote caused so much confusion that I won't be quoting from reference sources again or even giving links to my sources ...I realize it's bad form to use material from reference sources without citing proper attribution ...however if you read my first installment you might recall that ...I've got a 2% probability of dying next year ...and the "smart money" would wager on the side of me dying before my C7 does ...so I won't be wasting any more of my remaining life expectancy by citing reference sources ...but I will gladly take the time to answer questions about anything I post ...and now for the real business at hand!

The graph below gives the categories and amounts of engine frictional loss for a gasser and a naturally aspirated diesel for several operating loads. The pumping losses shown are caused by "air friction" and "pressure differences" ...and in naturally aspirated engines pumping loss increases as RPM^2 ...but in my turbo-diesel model I treat pumping loss as a separate non-frictional loss term ...because I'm interested in the frictional losses between moving surfaces which causes wear ...and in this category the frictional loss of the piston skirts/rings rubbing against the cylinder walls accounts for about 80% of the total frictional loss shown for the piston-crank assembly ...and this means the friction of the piston skirts/rings accounts for about 70% of the total engine friction!

Well piston skirt/ring friction causes heat build up ...and heat build up leads to more friction ...and there's also the heat load from the combustion to consider! The graph below is for a DI diesel with a Bore, Stroke, and Compression Ratio that's about the same as for a 7.3L engine ...and the graph gives the "percentage of heat flow" from the combustion chamber that various portions of a piston absorb ...and as can be seen the upper ring portions of the piston take the brunt of the heat load!

So considering the above graphs it's not surprising that in the course of a 7.3L engine's B90 life expectancy ...which is roughly 440K miles and 1 billion crankshaft revolutions ...the decline in the engine's durability and efficiency is largely determined by the wear of the piston skirts/rings and cylinder walls. As the piston skirts/rings and cylinder walls wear ...there's a gradual loss of FWHP ...and there's a gradual increase in fuel consumption, oil consumption, blowby, and exhaust emissions.

The wear rate of the piston skirts/rings and cylinder walls is initially high when an engine is new ...and during the break-in miles the wear rate gradually decreases ...and finally the wear rate reaches a fairly stable lower steady-state value during the remaining miles of the engine's life expectancy.

In addition to other features that I'll cover in future installments ...the picture below indicates the various forces that combine to determine the tangential friction force between the piston skirt/ring and the cylinder wall. The combustion pressure applies a pressure force to the top of the piston ...and this pressure force is applied via the piston pin to the rod. The reciprocating motion of the piston produces an inertial force that's applied by the rod to the piston pin. The net force in the rod times the sine of the angle between the rod and the cylinder vertical centerline gives the side-load force on the piston ...and multiplying the side-load force by the coefficient of friction gives the tangential friction force between the piston skirt/ring and the cylinder wall.

However as can be seen in this graph... http://ernesteugene.com/FTE3/Oil_Friction.jpg ...the coefficient of friction depends on the type of lubrication that is obtained between the piston skirt/ring and the cylinder wall ...and the lubrication type varies from mixed or boundary lubrication near TDC of the power stroke to full hydrodynamic lubrication during the center portions of the piston strokes. From here on if I refer to a picture I've already posted I'll give the link to it ...and clicking on that link should open the picture in a separate window.

The picture below shows the beginning of a power stroke ...and as can be seen the full value of the combustion pressure leaks behind the first compression ring and pushes that ring against the cylinder wall with a pressure force which adds to the spring tension force in the ring and also adds to the side-load force on the piston that was previously considered above ...and a lesser value of the combustion pressure leaks behind the second compression ring and pushes that ring against the cylinder wall with a somewhat lesser force compared to the force pushing the first compression ring ...and a even lesser value of the combustion pressure leaks behind the next ring etc... and for a healthy engine with a normal amount of blowby about 1% of the mass of cylinder gas winds up leaking down to the crankcase.

There're many mechanisms that contribute to the wear of the piston skirts/rings and cylinder walls. The three most important wear mechanisms are ...mixed or boundary lubrication, abrasion, and corrosion. Mixed or boundary lubrication occurs when the oil film between the piston skirts/rings and cylinder walls is thin enough to allow some metal-to-metal contact. Abrasion results from the cutting action of hard particles in the oil that are small enough to enter the clearance space between the piston skirts/rings and the cylinder walls. Corrosion results from adverse chemical reactions associated with the decomposition of diesel fuel and engine oil and corrosion is occurring all the time ...even when the engine isn't running!

Other than the B10 and B50 numbers for a T444E ...I haven't found any wear data for a 7.3L engine ...however by using normalized parameters such as piston speed, mean effective pressure, FWHP per piston area, FWHP per CID, and others ...I'm attempting to use measured data from test engines and from lab simulators that generate accelerated mechanical wear of piston skirts/rings and cylinder walls ...and results from mathematical wear models ...to shed some light on the potential wear performance of a 7.3L engine for various levels of FWHP generated at various values of RPM.

To help calculate these estimates ...I need the weight of a piston and the weight of a rod and the center-to-center length of a rod ...and to aid my analysis of piston friction I need for someone who has access to a 7.3L engine with the heads removed to use a torque wrench and measure the average TQ required to rotate the crankshaft about 90* or so and then repeat this measurement 4 or 5 times so I can average those results ...and I also need to know if a 7.3L engine uses an offset wrist pin ...and I'm beginning to think that to get this information I might need to start a thread on another forum where there's more interest and/or more knowledge about the innards of a 7.3L engine?

I'll start the next installment by giving some graphs of measured data on several diesel engines of oil film thickness and tangential friction force between the piston skirt/ring and the cylinder wall.

Thread

Thread Starter

Forum

Replies

Last Post

Jklnhyd

1973 - 1979 F-100 & Larger F-Series Trucks

768

06-13-2022 02:29 PM

akorcovelos

General NON-Automotive Conversation

4

11-01-2016 03:22 PM

1960, 73, 73l, born, classmates, diesel, engine, estimating, expectancy, expenctancy, high, life, living, median, milage, mileage, powerstroke