Bully AS-600 Side Step Installation

#1

#7

Trending Topics

#9

I bought a set of these, was gonna use them on my '77 too, then ran up on a set of unused Carr Super Hoops with a slightly duifferent mount. I gave the Bully ones to my BIL for Christmas, his wife was really excited. They'll work on his Dodge. Either way, I've looked at mounting real close, studied on it, and I have come to conclusion that on my '77, the lip that you cut provided a certain stiffness to that floor support which you bolted to.

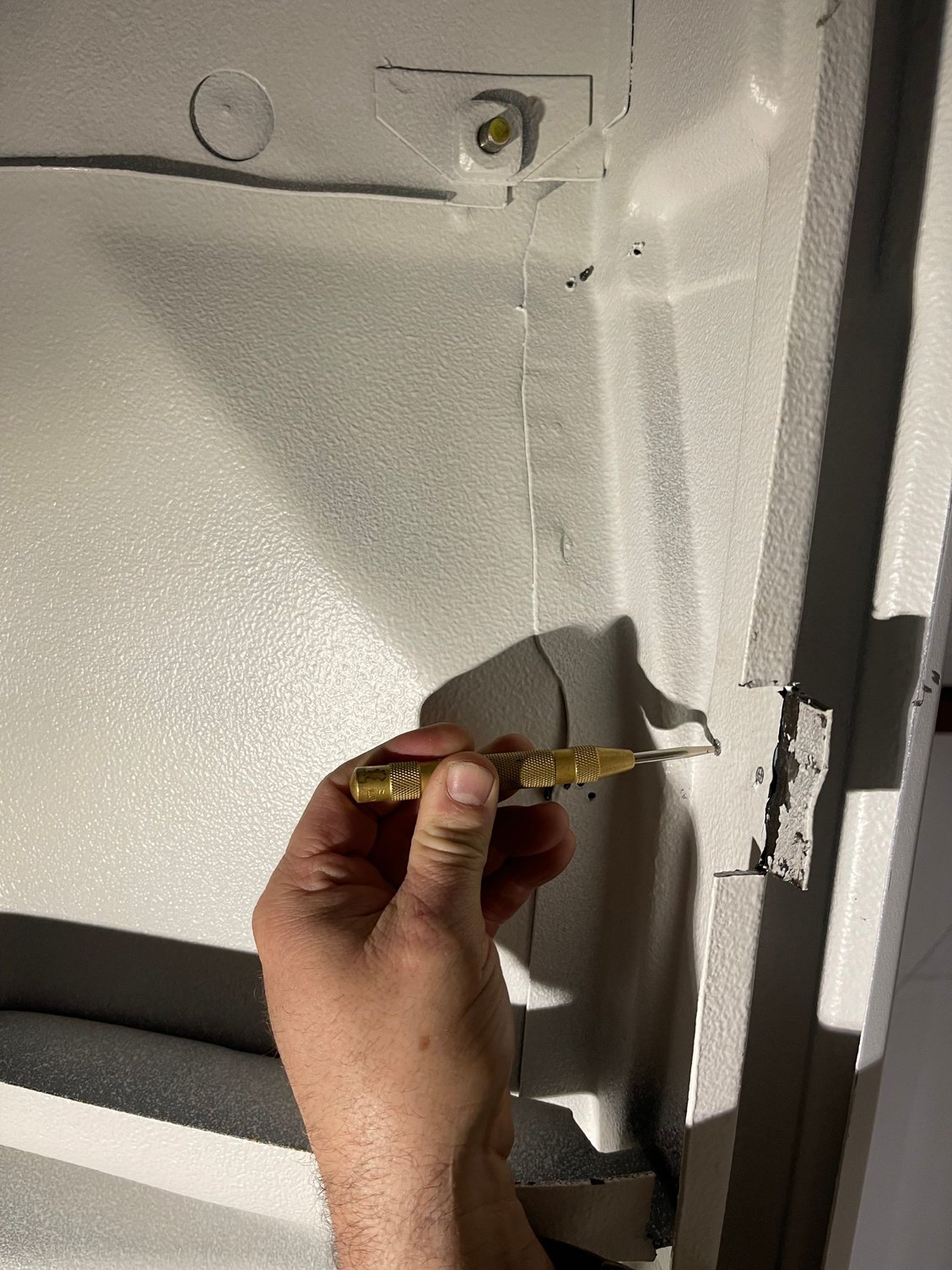

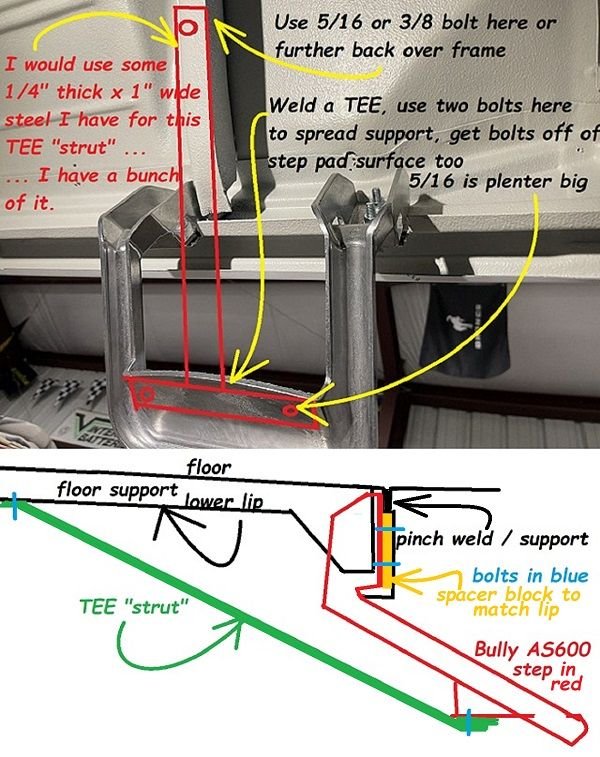

There is another side to side support that travels up and over the frame, it's part of the welded cab structure. I'm inclined to not cut that lip at all, but rather to add a fabricated "TEE" that will bolt to the step rear side over near ends with two 5/16" bolts and I'll put rubber between the steel and aluminum ... and use a third bolt up to the lip of the cross ways under cab support, it'll provide support to resist any tendency to sag or twist the pinch weld strip, and I took the liberty of using your photo to draw mine out, so clean it is. Years ago, I found a pile of 20-30 old store racks that were 4 feet long of 1/4"x1" steel, a 1/4" hole every inch the length. What stores hang stuff on. I cut the plates off the ends with a cut-off saw wheel on my 4.5" angle grinder.

Again, nice truck there, and maybe someone else is looking for ideas too. I know the pinch weld is thick as evidenced by your experience. My BIL's Dodge has boxed section rockers that support the pinch weld where our old Fords have a wide lip (the one you cut) and I suggested the same for under his truck. Triangles are the strongest geometric shapes, and this simple "strut" idea triangulates the mounting. Not a criticism at all, just something I've decided to include in my install, but first I need to get the face lift done.

Take Care ...

EDIT: I saw that in my haste last night to scratch out my idea, I drew the red bolted to a line that represented the end on a cross-cab under floor support, a mistake I rectified here with a revision. That step like lip above the notches cut to clear the step part can stay "uncut" if a spacer to match the rise of the step is used. Spacer could be made of aluminum or steel, would not have to be the exact same thickness as that upper step at pinch weld top, it could be same or thicker to miss the step.

The following users liked this post:

#11

#12

The only reason I cut the lip was to avoid putting the step up any higher. The upper hole would have went through into the door opening and been visible with the door open and interfered with the door seal. The steps do provide spacers and shims and a variety of bolts and screws for mounting. Probably a dozen ways these could be mounted. Always good to have more ideas and options on how to install these.

#13

The only reason I cut the lip was to avoid putting the step up any higher. The upper hole would have went through into the door opening and been visible with the door open and interfered with the door seal. The steps do provide spacers and shims and a variety of bolts and screws for mounting. Probably a dozen ways these could be mounted. Always good to have more ideas and options on how to install these.

... so I fixed it.

... so I fixed it.I like those new wheels too.

Thread

Thread Starter

Forum

Replies

Last Post

bigwin56f100

1948 - 1956 F1, F100 & Larger F-Series Trucks

6

10-06-2021 10:17 AM

65fordguy

1961 - 1966 F-100 & Larger F-Series Trucks

1

09-19-2010 02:42 PM