Oil breather

#31

Off on a tangent:

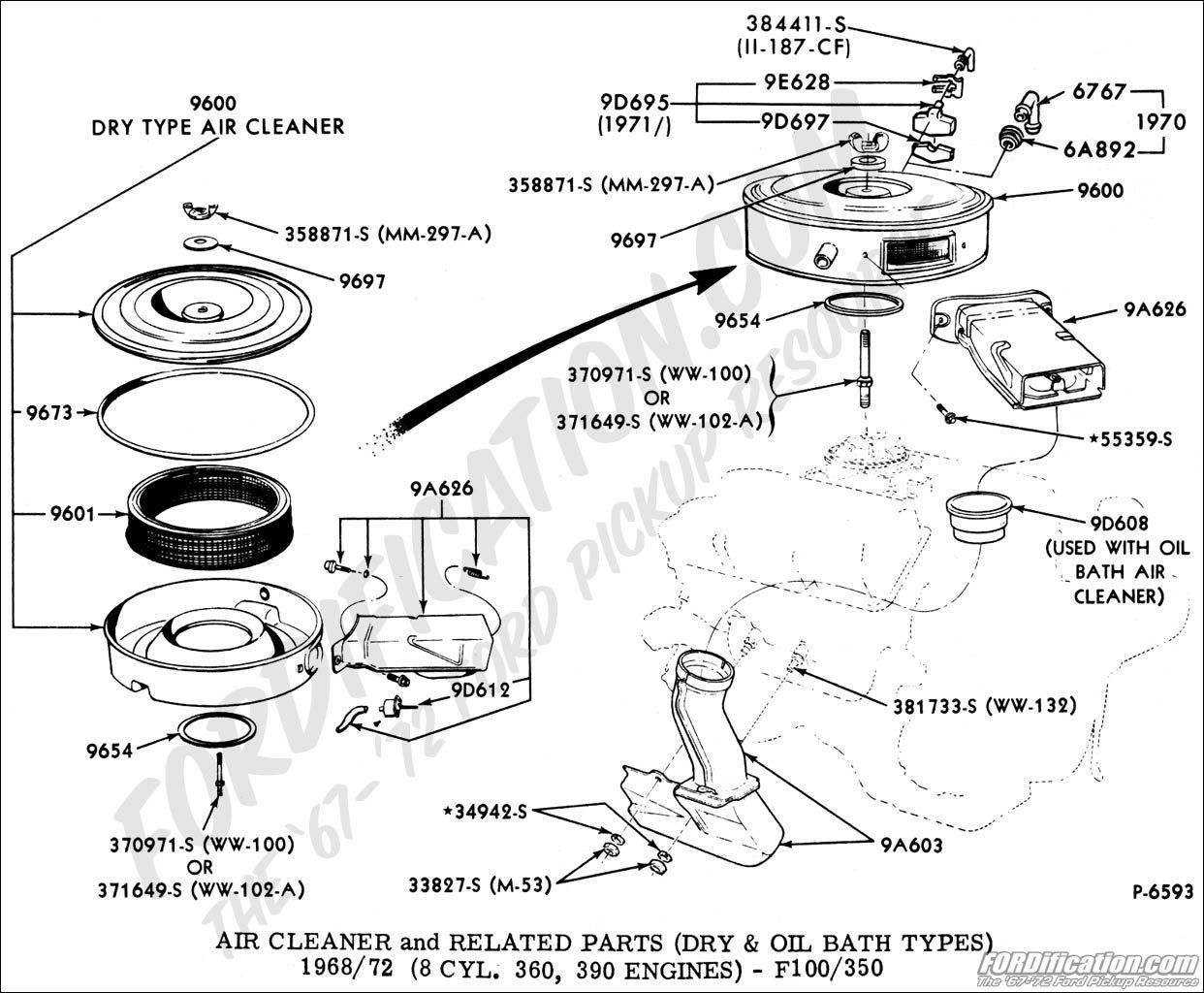

My '84 351W still has the factory air cleaner. Unlike aftermarket air cleaners, the filter sits fully enclosed inside the housing. However, the PCV system draws fresh air through a small separate filter outside the engine air filter, even though both sit inside the same housing.

Any idea why? PCV air could have been drawn from inside the big engine filter. This would have saved the expense of a separate PCV filter. But anytime a manufacturer spends extra money, there's usually a good reason. So I put on my orthopedic thinking cap.

My TheoryDuJOur™ involves oily fumes blowing back through the PCV system. Under normal conditions, air only travels through the PCV in one direction. But sometimes, especially with excessive blow-by on a worn engine, oily fumes can overwhelm the PCV system. For example, when the PCV valve is closed at idle, oily fumes still accumulate and escape via the system inlet filter. The inside of my truck's air cleaner housing definitely gets oily. Not real bad, but maybe once a year or so I'll need to wipe it clean. The face of the air filter also picks up a light film, too.

So my hunch is the PCV inlet is purposely located outside of the engine air filter to reduce the amount of oily fumes drawn directly into the carb. Also, if the PCV inlet was inside the main air filter, if that big filter became clogged, you'd develop a very strong suction at the PCV inlet.

Thoughts?

My '84 351W still has the factory air cleaner. Unlike aftermarket air cleaners, the filter sits fully enclosed inside the housing. However, the PCV system draws fresh air through a small separate filter outside the engine air filter, even though both sit inside the same housing.

Any idea why? PCV air could have been drawn from inside the big engine filter. This would have saved the expense of a separate PCV filter. But anytime a manufacturer spends extra money, there's usually a good reason. So I put on my orthopedic thinking cap.

My TheoryDuJOur™ involves oily fumes blowing back through the PCV system. Under normal conditions, air only travels through the PCV in one direction. But sometimes, especially with excessive blow-by on a worn engine, oily fumes can overwhelm the PCV system. For example, when the PCV valve is closed at idle, oily fumes still accumulate and escape via the system inlet filter. The inside of my truck's air cleaner housing definitely gets oily. Not real bad, but maybe once a year or so I'll need to wipe it clean. The face of the air filter also picks up a light film, too.

So my hunch is the PCV inlet is purposely located outside of the engine air filter to reduce the amount of oily fumes drawn directly into the carb. Also, if the PCV inlet was inside the main air filter, if that big filter became clogged, you'd develop a very strong suction at the PCV inlet.

Thoughts?

#32

You might be looking at two separate systems. Is there more than one place for hoses to connect? With one being inside the main flter?

On some engine setups the PCV pulls from behind the stock filter, whereas the EVAP/ Charcoal canister hose often connects to one of those separate semi-curved filter elements that sit just inside the housing.

I'm sure I could be wrong on that for our specific trucks (been awhile since I had my stock setup together), but I thought the separate filter was EVAP related.

Paul

#33

Ok, that's consistent with what others have said as well. Including for the early Broncos.

And while I do remember changing one out because it had become too oil soaked (after approx. 10 years of use though, so not too bad) I just did not remember it in the location where the PCV return was. But it must have been and my memory is just faulty.

Ask me about some obscure song from '68 and I'll probably remember it. Ask me about a part I have not looked at since '78 though, and I'll probably get it mixed up with some other part!

Thanks guys.

Paul

And while I do remember changing one out because it had become too oil soaked (after approx. 10 years of use though, so not too bad) I just did not remember it in the location where the PCV return was. But it must have been and my memory is just faulty.

Ask me about some obscure song from '68 and I'll probably remember it. Ask me about a part I have not looked at since '78 though, and I'll probably get it mixed up with some other part!

Thanks guys.

Paul

#34

And now back to the OP’s dilemma

So I gets to thinking some more. What would be the best option for the OP and his aftermarket air cleaner?

Around post #15, there was some discussion of rigging up a new fresh air supply line between the air cleaner and the existing connection on the valve cover. The drawback is the line would have to draw its air supply (watch it!) from inside the big air filter, and under certain conditions, oily fumes would be drawn directly into the carb inlet.

Or would he be better off to add some type of actual filter at the oil fill cap, where the PCV system is currently drawing unfiltered air into the crankcase?

We had lots of discussion about both methods, but no real consensus on which is probably best in this situation.

I’m leaning towards a filter at the oil fill cap. On my truck’s stock setup, even though a little bit of oil collects around the outer reaches of the air filter housing, I don’t see any evidence of oil getting past the big filter and into the carb inlet.

Around post #15, there was some discussion of rigging up a new fresh air supply line between the air cleaner and the existing connection on the valve cover. The drawback is the line would have to draw its air supply (watch it!) from inside the big air filter, and under certain conditions, oily fumes would be drawn directly into the carb inlet.

Or would he be better off to add some type of actual filter at the oil fill cap, where the PCV system is currently drawing unfiltered air into the crankcase?

We had lots of discussion about both methods, but no real consensus on which is probably best in this situation.

I’m leaning towards a filter at the oil fill cap. On my truck’s stock setup, even though a little bit of oil collects around the outer reaches of the air filter housing, I don’t see any evidence of oil getting past the big filter and into the carb inlet.

#35

So I gets to thinking some more. What would be the best option for the OP and his aftermarket air cleaner?

Around post #15, there was some discussion of rigging up a new fresh air supply line between the air cleaner and the existing connection on the valve cover. The drawback is the line would have to draw its air supply (watch it!) from inside the big air filter, and under certain conditions, oily fumes would be drawn directly into the carb inlet.

Or would he be better off to add some type of actual filter at the oil fill cap, where the PCV system is currently drawing unfiltered air into the crankcase?

We had lots of discussion about both methods, but no real consensus on which is probably best in this situation.

I’m leaning towards a filter at the oil fill cap. On my truck’s stock setup, even though a little bit of oil collects around the outer reaches of the air filter housing, I don’t see any evidence of oil getting past the big filter and into the carb inlet.

We had lots of discussion about both methods, but no real consensus on which is probably best in this situation.

I’m leaning towards a filter at the oil fill cap. On my truck’s stock setup, even though a little bit of oil collects around the outer reaches of the air filter housing, I don’t see any evidence of oil getting past the big filter and into the carb inlet.

IMO, I would find a quality replacement OPEN SYSTEM cap (STANT) and just let it go. The correct way to do it would be to find an OEM ACL.

#37

#39

Interesting I just completed a clean up of the jacked up vacuum, fuel,pvc lines. On my 351HO I used a carburetor spacer plate with a vacuum connection at the rear attached to the pcv valve and installed extended oil cap allowing me to use a vented push in oil cap. Seams to to be good so far went on a 426 mile trip to pickup a new car trailer and have no blowe by,

#40

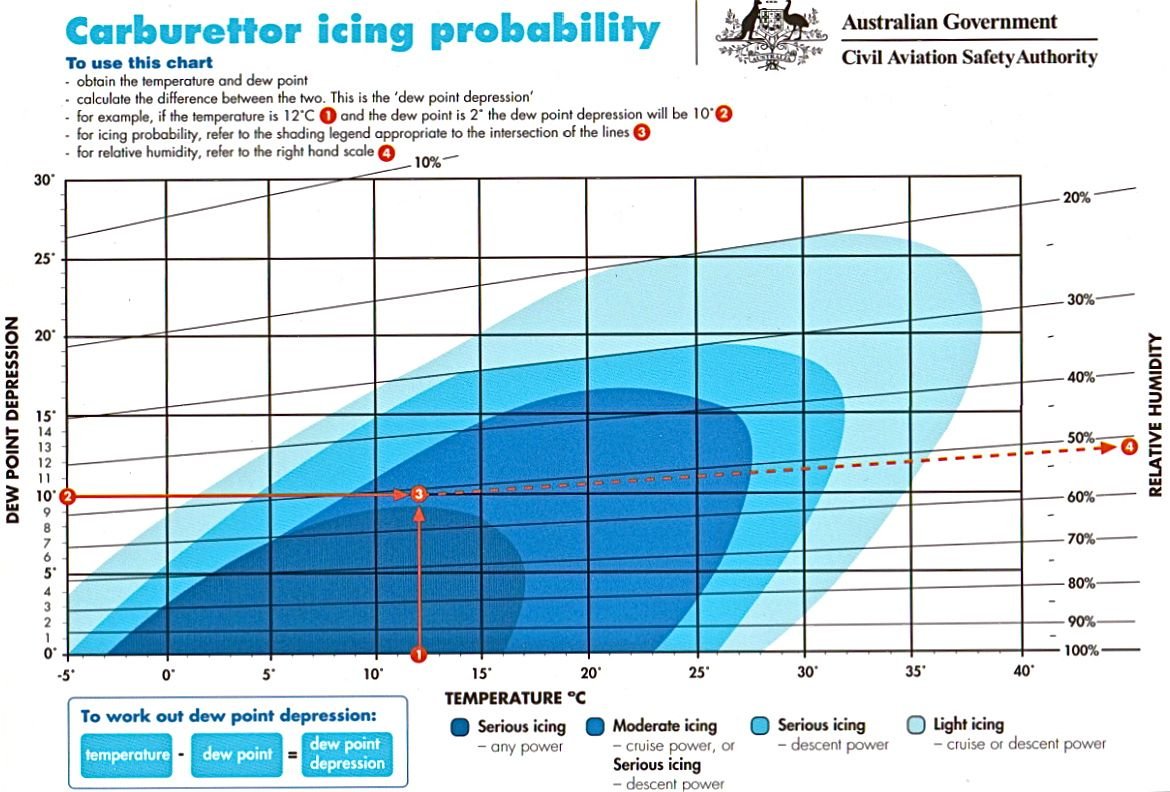

The provisions for feeding heated air to the induction system has been done since the late 50's/early '60s or when the national high way system was completed (the 2 are related).

Carburettor icing is caused by the temp drop due to fuel vaporization and the inherent temp drop due to the pressure drop in a venturi.

If the temperature in the venturi drops below freezing water vapour in the air can and will freeze on the venturi (carb body and the throttle blade/s.

This drop in temp can be as much as 70°F or 39°C so even with an ambient temp of 100°F/38°C outside it is possible to get carb icing under the right conditions. And this is long after the hot air stove has ceased feeding the engine heated air.

Icing is most likely to happen as the engine is warming up and at constant sustained RPM's such as on the highway. Even under ideal icing conditions with no warm air fed to the induction system driving around town in stop and go traffic the chances of carb icing occurring is just about zilch, as there is not long term sustained flow through the carb, for long enough periods of time to cool the venturi/carb down and residual engine heat, will heat the carb when it is idling. Now on an engine that is warming up all bets are off.

Icing is most likely to occur at sustained engine RPM's like in aircraft...

Pilots of piston-powered aircraft carry charts to tell them when they are at high risk of carb icing and to act accordingly. Even the Aussies issue these charts.

See below. Cause guess what Airplanes do not have hot air stoves they have carb heaters and carb temp gauges so the pilot can flip the heater on when he sees the temp of the carb nearing freezing.

So is the heat stove needed? Well, that depends on what kind of driving you do and where you live. Example you live in Vegas, or other dry climate, chances are you will never see carb icing no matter what sort of driving you do. I'm in the relatively dry climate of Northen Alberta and in the 30 plus years I have been here and running open element filters in all seasons I have experienced carb icing once and yes it was on the highway and a really humid day (fog) just below freezing outside. And I knew chances were I was going to experience it.

If your location sees high humidity 70% and above frequently then you will in all likely hood going to experience icing.

Like if you live somewhere like the east coast or the northwest and actually see a winter you are high risk for carb icing even around town.

And is icing a big deal, in an airplane yes lol , in a vehicle no, it is an annoyance though. As the icing will disrupt the flow of fuel and air into the engine. leading to low power lagged or no throttle response. The fix, simply turn the engine off for a min or so and let the residual heat in the motor melt the ice in the carb , takes a couple of seconds on a hot engine and up to min on a cool or cold engine.

So really the hot air stove is not "needed" but it is nice to have.

The hot air stove is one of those items that gets way overplayed for its significance with little to zero understanding of it's actual function or the conditions needed for it to fulfil it's intended purpose..

#42

He does not "need" it but it is advisable. The hot stove has nothing to do with it being an emissions era carb, it is there to mitigate the chance of carb icing, not eliminate but mitigate.

The provisions for feeding heated air to the induction system has been done since the late 50's/early 60's or when the national high way system was completed (the 2 are related) .

Carburettor icing is caused by the temp drop due to fuel vaporization and the inherent temp drop due to the pressure drop in a venturi.

If the temperature in the venturi drops below freezing water vapour in the air can and will freeze on the venturi (carb body and the throttle blade/s.

This drop in temp can be as much as 70°F or 39°C so even with an ambient temp of 100°F/38°C outside it is possible to get carb icing under the right conditions. And this is long after the hot air stove has ceased feeding the engine heated air.

Icing is most likely to happen as the engine is warming up and at constant sustained RPM's such as on the highway. Even under ideal icing conditions with no warm air fed to the induction system driving around town in stop and go traffic the chances of carb icing occurring is just about zilch, as there is not long term sustained flow through the carb for long enough periods of time to cool the venturi/carb down and residual engine heat the carb when it is idling. Now on an engine that is warming up all bets are off.

Icing is most likely to occur at sustained engine RPM's like in aircraft...

Pilots of piston-powered aircraft carry charts to tell them when they are at high risk of carb icing and to act accordingly. Even the Aussies issue these charts.

See below. Cause guess what Airplanes do not have hot air stoves they have carb heaters and carb temp gauges so the pilot can flip the heater on when he sees the temp of the carb nearing freezing.

So is the heat stove needed? Well, that depends on what kind of driving you do and where you live. Example you live in Vegas, or other dry climate, chances are you will never see carb icing no matter what sort of driving you do. I'm in the relatively dry climate of Northen Alberta and in the 30 plus years I have been here and running open element filters in all seasons I have experienced carb icing once and yes it was on the highway and a really humid day (fog) just below freezing outside. And I knew chances where I was going to experience it.

If your location see high humidity 70% and above frequently then you will in all likely hood experience icing.

Like if you live somewhere like the east coast or the northwest and actually see a winter you are high risk for carb icing even around town.

And is icing a big deal, in an airplane yes lol , in a vehicle no, it is an annoyance though. As the icing will disrupt the flow of fuel and air into the engine. leading to low power lagged or no throttle response. The fix, simply turn the engine off for a min or so and let the residual heat in the motor melt the ice in the carb , takes a couple of seconds on a hot engine and up to min on a cool or cold engine.

So really the hot air stove is not "needed" but it is nice to have.

The hot air stove is one of those items that gets way overplayed for its significance with little to zero understanding of it's actual function or the conditions needed for it to fulfil it's intended purpose..

The provisions for feeding heated air to the induction system has been done since the late 50's/early 60's or when the national high way system was completed (the 2 are related) .

Carburettor icing is caused by the temp drop due to fuel vaporization and the inherent temp drop due to the pressure drop in a venturi.

If the temperature in the venturi drops below freezing water vapour in the air can and will freeze on the venturi (carb body and the throttle blade/s.

This drop in temp can be as much as 70°F or 39°C so even with an ambient temp of 100°F/38°C outside it is possible to get carb icing under the right conditions. And this is long after the hot air stove has ceased feeding the engine heated air.

Icing is most likely to happen as the engine is warming up and at constant sustained RPM's such as on the highway. Even under ideal icing conditions with no warm air fed to the induction system driving around town in stop and go traffic the chances of carb icing occurring is just about zilch, as there is not long term sustained flow through the carb for long enough periods of time to cool the venturi/carb down and residual engine heat the carb when it is idling. Now on an engine that is warming up all bets are off.

Icing is most likely to occur at sustained engine RPM's like in aircraft...

Pilots of piston-powered aircraft carry charts to tell them when they are at high risk of carb icing and to act accordingly. Even the Aussies issue these charts.

See below. Cause guess what Airplanes do not have hot air stoves they have carb heaters and carb temp gauges so the pilot can flip the heater on when he sees the temp of the carb nearing freezing.

So is the heat stove needed? Well, that depends on what kind of driving you do and where you live. Example you live in Vegas, or other dry climate, chances are you will never see carb icing no matter what sort of driving you do. I'm in the relatively dry climate of Northen Alberta and in the 30 plus years I have been here and running open element filters in all seasons I have experienced carb icing once and yes it was on the highway and a really humid day (fog) just below freezing outside. And I knew chances where I was going to experience it.

If your location see high humidity 70% and above frequently then you will in all likely hood experience icing.

Like if you live somewhere like the east coast or the northwest and actually see a winter you are high risk for carb icing even around town.

And is icing a big deal, in an airplane yes lol , in a vehicle no, it is an annoyance though. As the icing will disrupt the flow of fuel and air into the engine. leading to low power lagged or no throttle response. The fix, simply turn the engine off for a min or so and let the residual heat in the motor melt the ice in the carb , takes a couple of seconds on a hot engine and up to min on a cool or cold engine.

So really the hot air stove is not "needed" but it is nice to have.

The hot air stove is one of those items that gets way overplayed for its significance with little to zero understanding of it's actual function or the conditions needed for it to fulfil it's intended purpose..

#44

Again not true. The snorkel was introduced in those years when they moved away from the 160° and 180° degrees thermostats and moved to the 192° stats increasing under hood heat. And not all vehicles got them either not by a long shot.

Sucking in underhood heat will richen the mixture. higher temps less oxygen in the air, less burnt fuel, but not enough to upset the mixture drastically until things get really hot then the next issue will rear it's head first. The real reason this was done, to prevent vapour stall out in the carb due to the higher underhood temps especially once they started packing thermactor plumbing under the hood or adding A/C. This is especially a problem in warmer locations.

And in 1968 the ONLY state concerned about tailpipe emissions was California and no changes were made to fuel-air mixtures what was added was the thermactor system that burnt a portion of the unburnt hydrocarbons in the exhaust manifold. This right in the middle of the HP war and fuel air mixtures were actually getting richer, not leaner. they did not start leaning things out till the early '70s and even then it was not much, in the mid '70s is when things really went leaner.

#45

Great pic of carb icing and the effects of it. And being in rather humid Virgina no surprise. What temps were you having issues at? I suspect right around freezing or just above.