76 high boy 360 4 speed manual problem

#1

76 high boy 360 4 speed manual problem

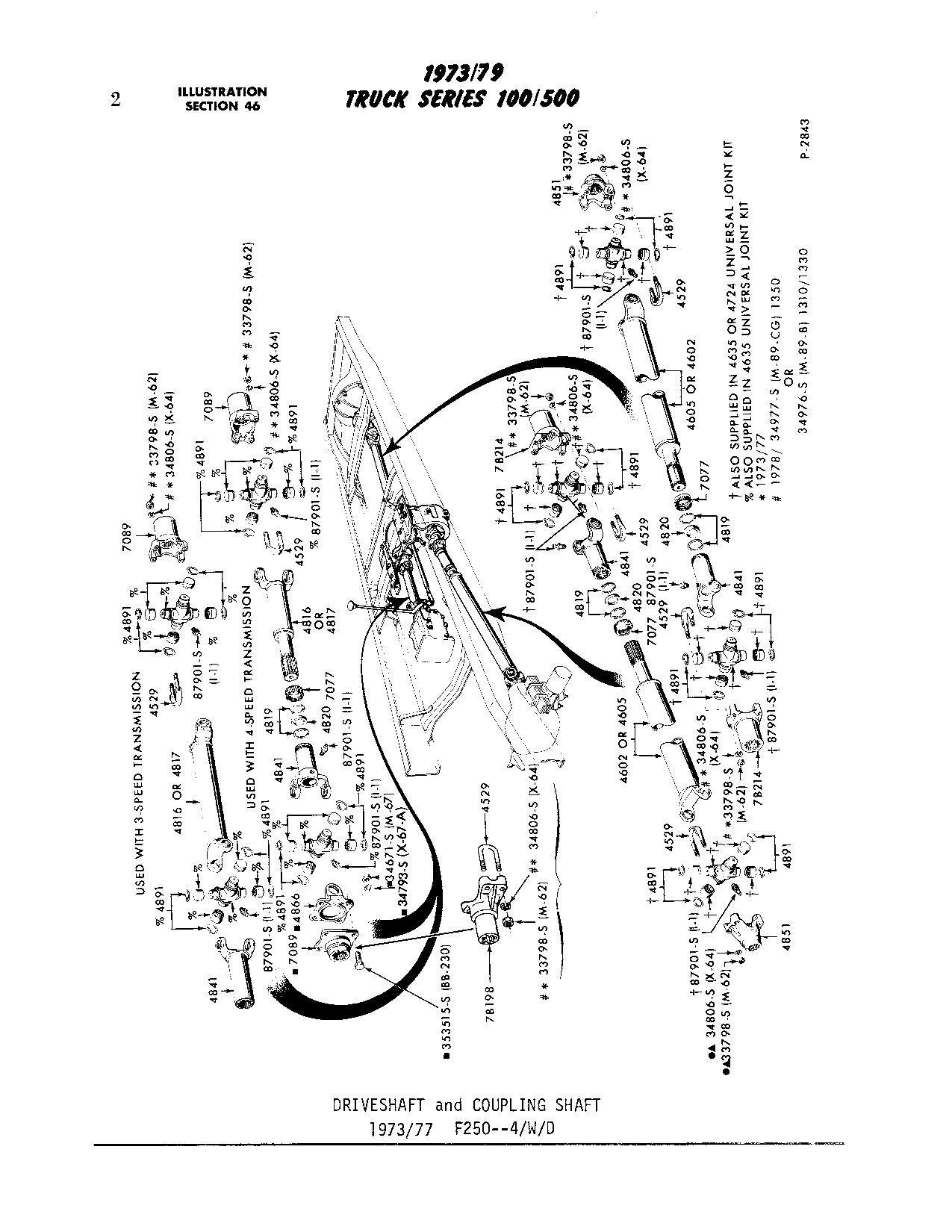

Recently picked up this truck and been messing and messing with it an can't get it to move, clutch is working fine and have side plate off transmission and can go through all the gears just fine and see them moving/working. But won't spin the driveshaft. Have a ton of driveshaft slop in tail shaft and spins freely when in gear but if I push it in towards tranny it trys to grab and grinds. Any advice much appreciated.l!

#3

#4

Since this is a 4wd truck, have you verified that the transfer case is fully in 2wd or 4wd mode, and not Neutral?

If your t-case is in neutral you get nothing past the trans.

Since this is a divorced case though, with an intermediate driveshaft, I'm guessing this is the shaft you're speaking of when you were spinning it? If so, then yes when the trans is in gear you should not be able to turn it by hand. However with the engine running you would see the shaft spin but the rear shaft to the rear wheels would not.

Your description does in fact sound like the transmission's tailshaft is snapped, but I thought I'd bring up much less expensive solutions before we have to go there!

Good luck. The good news is that I think the rear of the transmission is pretty easy to take apart. Never done it, but it looks simple enough.

Famous last words!

Paul

If your t-case is in neutral you get nothing past the trans.

Since this is a divorced case though, with an intermediate driveshaft, I'm guessing this is the shaft you're speaking of when you were spinning it? If so, then yes when the trans is in gear you should not be able to turn it by hand. However with the engine running you would see the shaft spin but the rear shaft to the rear wheels would not.

Your description does in fact sound like the transmission's tailshaft is snapped, but I thought I'd bring up much less expensive solutions before we have to go there!

Good luck. The good news is that I think the rear of the transmission is pretty easy to take apart. Never done it, but it looks simple enough.

Famous last words!

Paul

#5

Paul, I'm terrible at wording descriptions for this kind of stuff haha, but yes intermediate driveshaft never spins in gear, but can manually spin it while in gear. And I'd have to agree the shaft is pry broke inside. Hoping to find someone that has seen this issue before cause it cannot be the first time it's happened.

#7

Trending Topics

#8

TRANS code stamped on the Warranty Plate, riveted to the left door face below the latch.

A = New Process 435 (2WD & 4WD); F = Warner T-18 (2WD).

Both of these trannies were introduced in 1965. Originally, the T-18 had reverse up towards the dash, while the NP435 had reverse down towards the seat, but...

Sometime in the early 1970's, the T-18's reverse shift pattern changed. By 1973, it too has reverse down towards the seat.

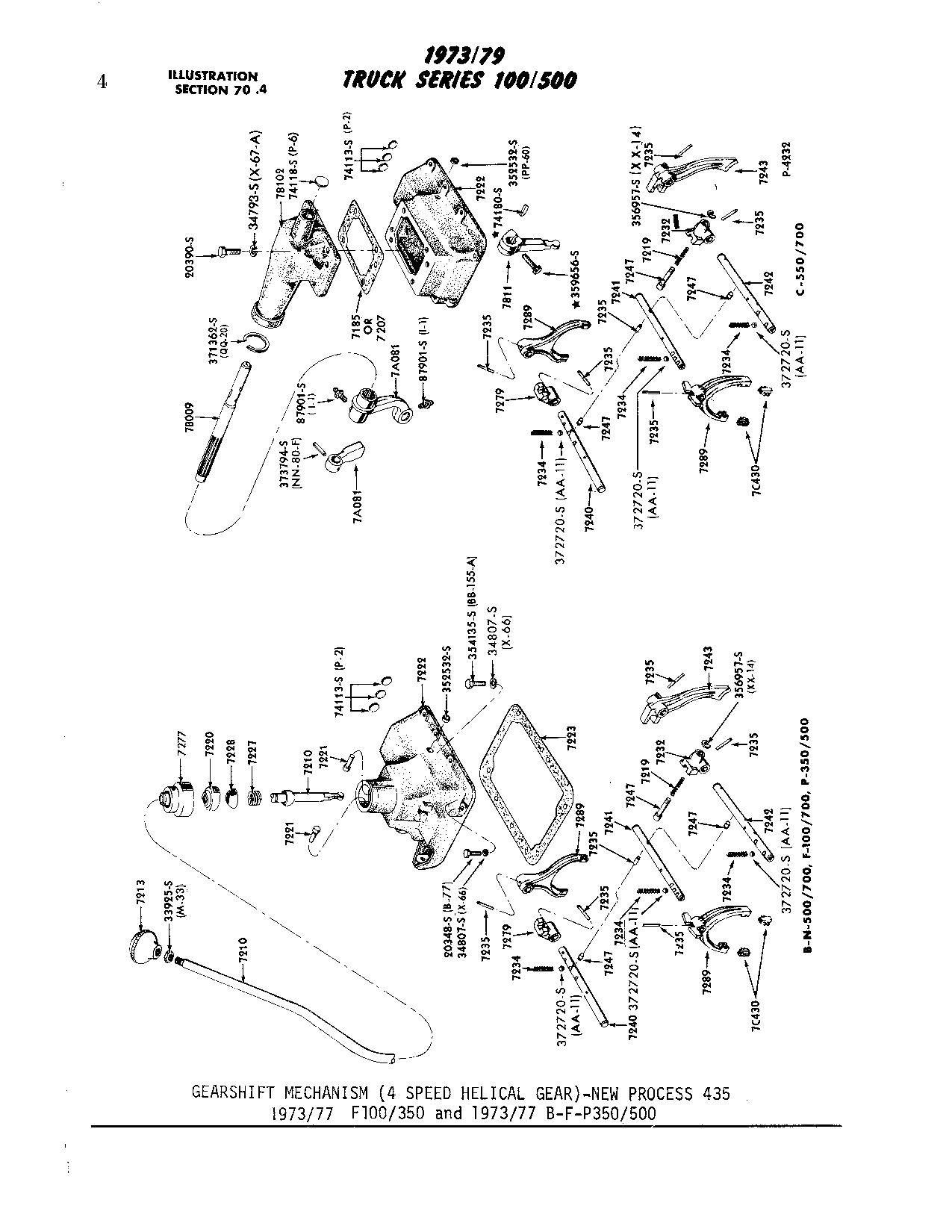

T-18: Shift lever retainer cap threads off/on.

NP435: Shift lever retainer cap has two notches, it's retained to the shift tower with two pins.

To remove this cap, it must be pressed down by hand and held down while turning it counterclockwise to remove it.

People unaware use pliers or channel locks to remove it, which tears out one or both of the notches. Not pleasant!

Pic: NP435 shift lever retainer cap (7220) and two pins (7221).

#9

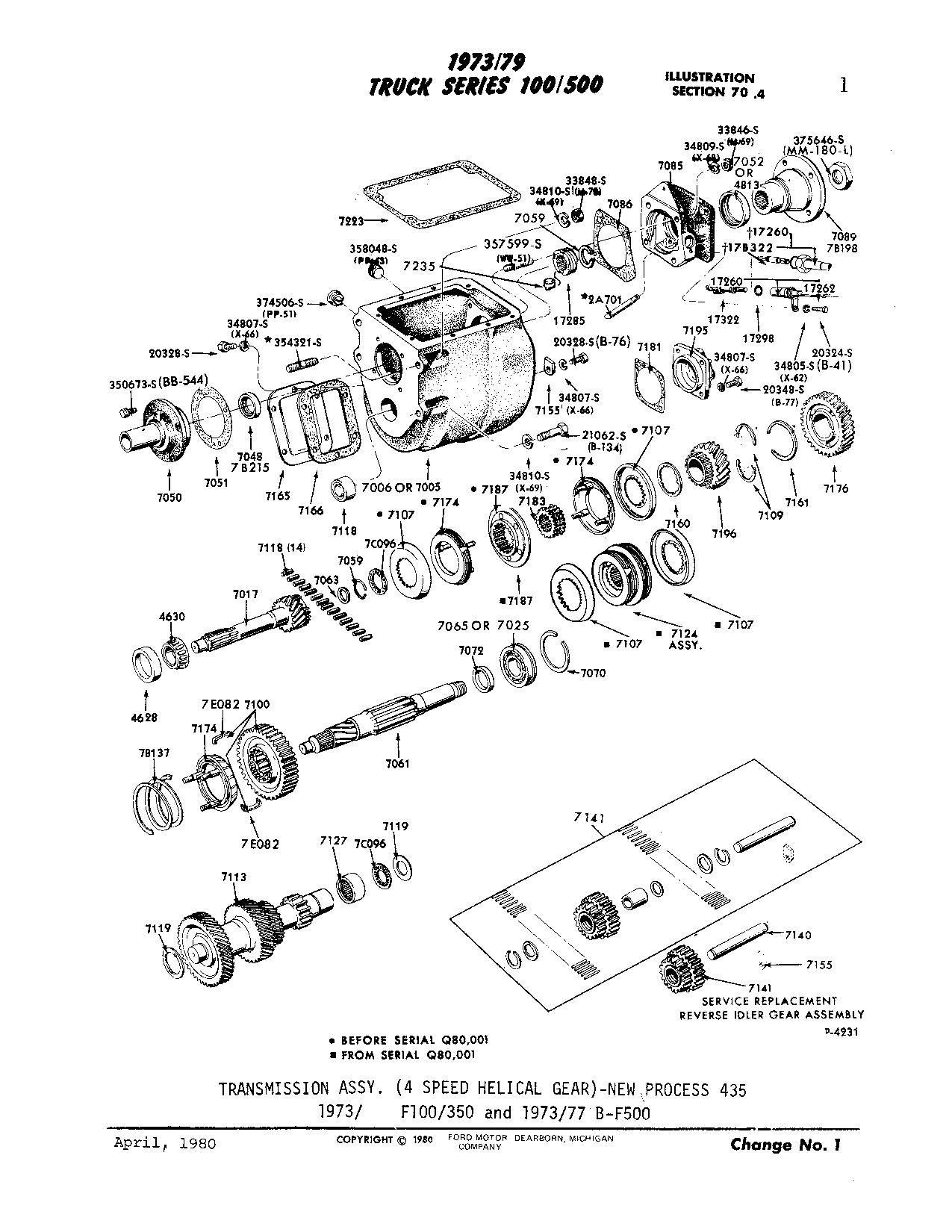

I looked up the trans applications, says New Process 435 (NP435) for 1967/77 F250 4WD (High Boys).

TRANS code stamped on the Warranty Plate, riveted to the left door face below the latch.

A = New Process 435 (2WD & 4WD); F = Warner T-18 (2WD).

Both of these trannies were introduced in 1965. Originally, the T-18 had reverse up towards the dash, while the NP435 had reverse down towards the seat, but...

Sometime in the early 1970's, the T-18's reverse shift pattern changed. By 1973, it too has reverse down towards the seat.

T-18: Shift lever retainer cap threads off/on.

NP435: Shift lever retainer cap has two notches, is retained to the tower with two pins.

To remove this cap, it must be pressed down by hand and held down while turning it counterclockwise to remove it.

People unaware use pliers or channel locks to remove it, which tears out one or both of the notches. Not pleasant!

TRANS code stamped on the Warranty Plate, riveted to the left door face below the latch.

A = New Process 435 (2WD & 4WD); F = Warner T-18 (2WD).

Both of these trannies were introduced in 1965. Originally, the T-18 had reverse up towards the dash, while the NP435 had reverse down towards the seat, but...

Sometime in the early 1970's, the T-18's reverse shift pattern changed. By 1973, it too has reverse down towards the seat.

T-18: Shift lever retainer cap threads off/on.

NP435: Shift lever retainer cap has two notches, is retained to the tower with two pins.

To remove this cap, it must be pressed down by hand and held down while turning it counterclockwise to remove it.

People unaware use pliers or channel locks to remove it, which tears out one or both of the notches. Not pleasant!

#11

I suppose the best scenario would be if somehow the internal splines on the output yoke have stripped. But I don't think I've ever see that happen. Or at least not without some damage to the output shaft anyway.

Frankly, I've never actually seen an NP435 with a broken tailshaft either. But that seems the most likely scenario.

Of course, it could be the more central to the internals, but my feeling is that if it was, you'd have drive in at least one or two forward speeds still. Not zero in all gears.

Sorry if it turns out that the only way to find out is to pull things apart. But definitely let us know what you find! I think we're all interested to know what can happen to a big beefy truck trans like this.

Paul

Frankly, I've never actually seen an NP435 with a broken tailshaft either. But that seems the most likely scenario.

Of course, it could be the more central to the internals, but my feeling is that if it was, you'd have drive in at least one or two forward speeds still. Not zero in all gears.

Sorry if it turns out that the only way to find out is to pull things apart. But definitely let us know what you find! I think we're all interested to know what can happen to a big beefy truck trans like this.

Paul

#12

I suppose the best scenario would be if somehow the internal splines on the output yoke have stripped. But I don't think I've ever see that happen. Or at least not without some damage to the output shaft anyway.

Frankly, I've never actually seen an NP435 with a broken tailshaft either. But that seems the most likely scenario.

Of course, it could be the more central to the internals, but my feeling is that if it was, you'd have drive in at least one or two forward speeds still. Not zero in all gears.

Sorry if it turns out that the only way to find out is to pull things apart. But definitely let us know what you find! I think we're all interested to know what can happen to a big beefy truck trans like this.

Paul

Frankly, I've never actually seen an NP435 with a broken tailshaft either. But that seems the most likely scenario.

Of course, it could be the more central to the internals, but my feeling is that if it was, you'd have drive in at least one or two forward speeds still. Not zero in all gears.

Sorry if it turns out that the only way to find out is to pull things apart. But definitely let us know what you find! I think we're all interested to know what can happen to a big beefy truck trans like this.

Paul

#13

Sorry, but I don't buy that. Taller has nothing to do with the intermediate driveshaft as the angle of the dangle, so to speak, does not change at all with suspension/ride height. It's a fixed point between the two semi-rigidly mounted gear boxes.

There really is no slide needed. Other than just to accommodate the flex of the mounts.

I suppose if the condition of the mounts deteriorates beyond a certain point, you could get too much flex for a shaft with no slip joint. And if I'm not mistaken, neither the output or input yokes are slip-yokes either. Correct? They're bolted right to the gear boxes?

Still sounds fishy, but I can't claim to know more about, or have seen more transmissions than your tranny guy. Especially the "old guy" in the group.

I'm willing to learn too.

Yikes! A wedding coming up, eh? Better focus.

No pressure of course.. But we can't wait to hear back about your truck!

Best of luck in your new venture!

Paul

There really is no slide needed. Other than just to accommodate the flex of the mounts.

I suppose if the condition of the mounts deteriorates beyond a certain point, you could get too much flex for a shaft with no slip joint. And if I'm not mistaken, neither the output or input yokes are slip-yokes either. Correct? They're bolted right to the gear boxes?

Still sounds fishy, but I can't claim to know more about, or have seen more transmissions than your tranny guy. Especially the "old guy" in the group.

I'm willing to learn too.

Yikes! A wedding coming up, eh? Better focus.

No pressure of course.. But we can't wait to hear back about your truck!

Best of luck in your new venture!

Paul

#15

If it's like I think it is, you have to have the entire trans out so you can remove, or at least access, the input shaft too.

They are separate, but interlinked with floating roller bearings helping support the two in the middle. If you simply pulled the rear tailshaft out (which I don't think you can do anyway) all the bearings would fall into the case.

As said though, I don't think you can simply pull the output all the way out because of it's meshing with the idler shaft and perhaps even being too large for the rear opening, which is the bearing bore.

I might be wrong on the details with this particular trans, but the 2-shaft concept is still valid I think so you will have to remove the trans for servicing.

Paul

They are separate, but interlinked with floating roller bearings helping support the two in the middle. If you simply pulled the rear tailshaft out (which I don't think you can do anyway) all the bearings would fall into the case.

As said though, I don't think you can simply pull the output all the way out because of it's meshing with the idler shaft and perhaps even being too large for the rear opening, which is the bearing bore.

I might be wrong on the details with this particular trans, but the 2-shaft concept is still valid I think so you will have to remove the trans for servicing.

Paul

Thread

Thread Starter

Forum

Replies

Last Post

TrevorK

Clutch, Transmission, Differential, Axle & Transfer Case

3

09-03-2017 09:40 PM

jlaudio_f100

1973 - 1979 F-100 & Larger F-Series Trucks

8

02-28-2010 06:01 PM

72F250Highboy

1967 - 1972 F-100 & Larger F-Series Trucks

15

12-30-2009 01:19 PM

zigzkidz

1980 - 1986 Bullnose F100, F150 & Larger F-Series Trucks

3

10-14-2007 07:56 AM

User 71024

1973 - 1979 F-100 & Larger F-Series Trucks

15

03-06-2006 03:33 PM