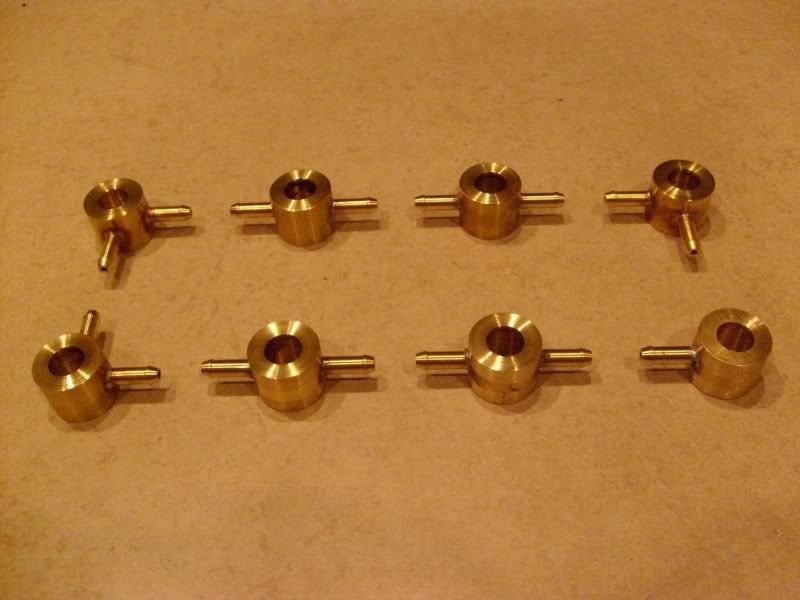

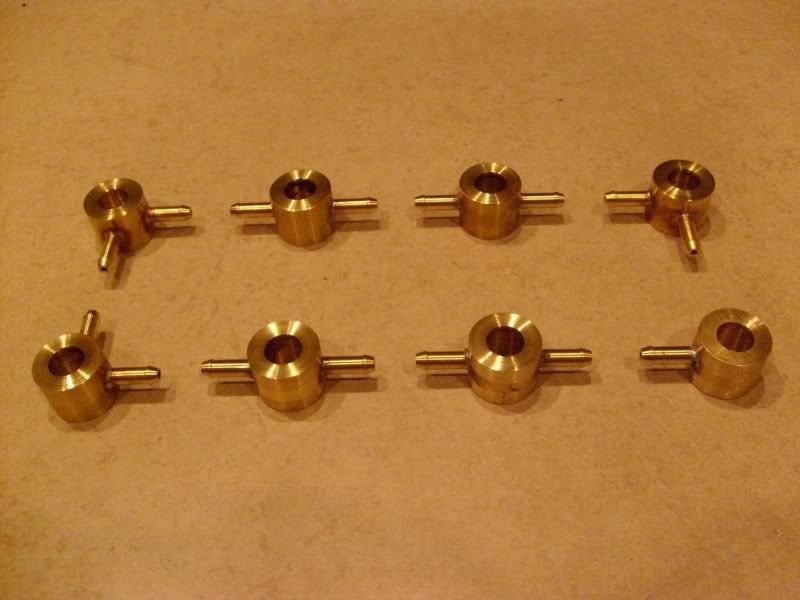

Return Caps Rev. 1.0

#1

Return Caps Rev. 1.0

They've finally arrived...

Sorry about the poor quality Samsung P&S pics... The caps turned out quite well. Revision 1.0 is a material change to brass. After I showed him the last round of backyard TIG welding, my dad decided to change materials and silver solder them himself. I couldn't get the flux off with the non-abrasive scotch brite pads I have.

Sorry about the poor quality Samsung P&S pics... The caps turned out quite well. Revision 1.0 is a material change to brass. After I showed him the last round of backyard TIG welding, my dad decided to change materials and silver solder them himself. I couldn't get the flux off with the non-abrasive scotch brite pads I have.

#3

I was wondering what happen with the follow up. Nice proto-types. Do you have some Viton #111 o-rings (16) to try them out? They appear pretty thick in the wall, he could probable turn the O.D. down some to save bulkiness which may cause premature o-ring failure from vibration. Keep us updated and see if he's willing to make sets for resale after some testing.

#5

Yep, 42 viton o-rings left for testing these.

The barbs sit inside a tight clearance hole and the solder runs in after heating creating an air/water tight seal. That's the reason for the thickness. I suppose he could've stepped it down a bit away from the barb holes.

I thought he was going to fin these like he did the aluminum, but he was in a hurry due to all the other work he has. He wants to know if they work or not. He's actually making another few aluminum ones and experimenting with brazing/soldering aluminum. If he can do it, he'll send me a complete set of aluminum caps too.

The barbs sit inside a tight clearance hole and the solder runs in after heating creating an air/water tight seal. That's the reason for the thickness. I suppose he could've stepped it down a bit away from the barb holes.

I thought he was going to fin these like he did the aluminum, but he was in a hurry due to all the other work he has. He wants to know if they work or not. He's actually making another few aluminum ones and experimenting with brazing/soldering aluminum. If he can do it, he'll send me a complete set of aluminum caps too.

#7

Trending Topics

#9

#11

Success

Got them installed yesterday after doing the valve cover gaskets, retorquing the rocker bolts, installing new glowplugs & injectors.

No leaks so far. We used the average tolerance between all plastic caps. Installing these was a bit more difficult because they're not plastic and don't give at all when pushing them over the o-rings. So you don't get that snap, but they've been machined so when the fuel lines are tightened, the caps will seat properly. I actually gave them a few taps with a very small brass hammer. You're able to turn them by hand when they're installed. I have not measured their temperature since running them.

No leaks so far. We used the average tolerance between all plastic caps. Installing these was a bit more difficult because they're not plastic and don't give at all when pushing them over the o-rings. So you don't get that snap, but they've been machined so when the fuel lines are tightened, the caps will seat properly. I actually gave them a few taps with a very small brass hammer. You're able to turn them by hand when they're installed. I have not measured their temperature since running them.

#12

Got them installed yesterday after doing the valve cover gaskets, retorquing the rocker bolts, installing new glowplugs & injectors.

No leaks so far. We used the average tolerance between all plastic caps. Installing these was a bit more difficult because they're not plastic and don't give at all when pushing them over the o-rings. So you don't get that snap, but they've been machined so when the fuel lines are tightened, the caps will seat properly. I actually gave them a few taps with a very small brass hammer. You're able to turn them by hand when they're installed. I have not measured their temperature since running them.

No leaks so far. We used the average tolerance between all plastic caps. Installing these was a bit more difficult because they're not plastic and don't give at all when pushing them over the o-rings. So you don't get that snap, but they've been machined so when the fuel lines are tightened, the caps will seat properly. I actually gave them a few taps with a very small brass hammer. You're able to turn them by hand when they're installed. I have not measured their temperature since running them.

your going to get a few pms i bet now,with people begging you to make them a set.

#13

maybe your dad can make me the 2nd set and send them when he quotes you on those pto extender coolers

maybe your dad can make me the 2nd set and send them when he quotes you on those pto extender coolers